Welding & Repair

The correct use of equipment and appropriate user competence are key factors in safe welding operations. Safety remains a primary consideration to support the protection of crew, vessel, and cargo.

A comprehensive range of welding equipment supports a wide variety of onboard welding applications. Effective welding practices contribute to improved safety and operational efficiency, helping to support cost control by reducing repair downtime and limiting risks to crew, cargo, and the vessel.

Welding equipment is designed in accordance with applicable maritime safety regulations, with technical information made available to end users to support correct and safe use of the equipment.

For all enquiries

Featured Offers

Welding Safety Inspection

A periodic safety inspection of onboard welding equipment is available to assess safety and operational conditions. The welding safety inspection is conducted as a confidential review of electric arc and gas welding equipment installed on board the vessel.

Our Solutions

Air Tools & Workshop Equipment

Air tools and workshop equipment support a broad range of everyday maintenance and repair tasks. Low-vibration air tools are available to support safer needle and chisel scaling operations by helping to reduce exposure to high vibration levels and associated risks such as Hand-Arm Vibration Syndrome (HAVS).

Cold Repair System

Cold repair compounds and leak-stopping solutions can be used to support temporary and permanent repair needs on board vessels, particularly in situations where welding is not feasible. These solutions are suitable for use on base materials that cannot be welded, in areas where hot work is restricted, or where conventional welding setup is impractical.

Arc Welding Consumables

A broad selection of arc welding consumables is available to support routine maintenance welding on board vessels. Proper storage solutions, including electrode cabinets, help maintain controlled conditions for welding consumables and electrodes. Heating cabinets and compact electrode dryers can be used to limit moisture absorption and to dry electrodes that have been exposed to moisture.

Arc Welding Equipment

Arc welding and plasma cutting equipment is suitable for use in maritime environments, supporting a range of onboard welding applications. Integrated protection features, such as Total Protection (TP), help reduce the risk of equipment issues related to voltage fluctuations. In addition, built-in Voltage Reduction Device (VRD) functions maintain reduced open-circuit voltage levels to support safer welding operations.

A range of associated welding safety equipment and consumables is also available to support safe and effective welding activities on board.

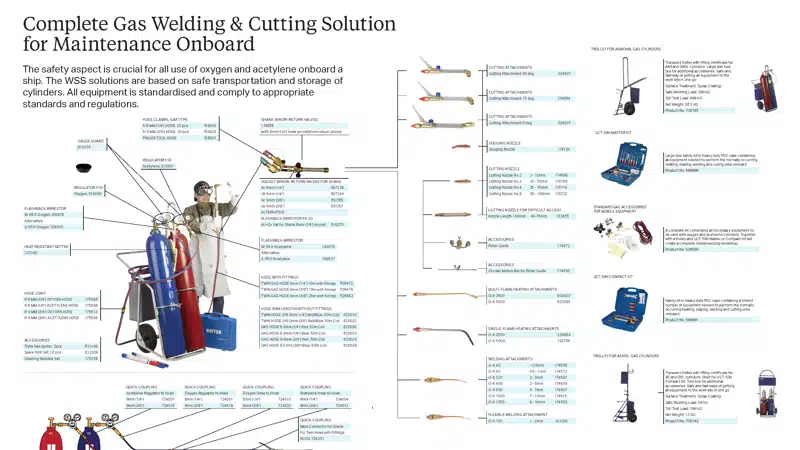

Gas Welding, Brazing & Cutting

Gas regulators and flashback arrestors support stable gas flow and contribute to safer gas welding and cutting operations. Lifting-certified transportation solutions, together with appropriate accessories for gas cylinders and gas welding and cutting equipment, support the safe handling and movement of cylinders on board the vessel.

Fartak B.O insights

Avoid the risk of electrocution

Welding at sea carries a range of safety hazards—not least the ever-present risk of electrocution. The good news is that electrocution injuries are completely avoidable with the right safety precautions. Let’s look at some common mistakes that heighten electrocution risk, and how welders can take steps to stay safe.

Staying compliant with RISQ 2.0 for welding safety

With the new RISQ 2.0 update, pressure regulators and flashback arrestors must be inspected annually and replaced every five years after the manufacturing date to prevent degradation and leakage. When was the last time you conducted an inspection? Find out how you can stay compliant.

Safety update for welding on Tankers

What are the revisions in OCIMF SIRE 2.0 and what actions do you need to take to stay compliant?

Choosing the right shielding gas for your welding needs on board

Arc welding processes commonly used by vessel crew, such as TIG and MIG/MAG welding, require the use of a shielding gas primarily to shield and protect the molten weld pool from the surrounding atmosphere. Let’s examine the key factors to consider in selecting the right shielding gas for your crew’s welding needs on board.

Technical Updates

Understanding the danger of Adiabatic Compression

Safety measures when connecting oxygen cylinders to freestanding regulators or high pressure slings in Gas Distribution Systems (GDS)

Customer Tools

Welding Handbook

A solid understanding of modern welding techniques is an important skill for onboard operations. A welding handbook can provide practical guidance on contemporary welding methods and related processes, serving as a reference source for addressing common onboard welding challenges and supporting informed decision-making.

Gas Welding & Cutting Solutions Poster

Safety measures are crucial for all use of oxygen and acetylene onboard a ship – get to know our various tools, accessories and safety equipment related to gas and cutting solutions onboard.

Safety Checklist for Welding & Thermal Processes

Do not operate equipment for welding or related thermal processes unless you are thoroughly familiar with the process, the equipment, rules and regulations related to the process and equipment; including proper use of accessories. Preparation for hot-work onboard should include, without being limited to, the points in this checklist to ensure safe operation.

Need advice?

With experienced teams operating across multiple port locations, practical local knowledge and industry expertise are applied to identify appropriate and effective solutions tailored to operational requirements.