Cleaning Solutions

Cleaning chemicals and equipment are selected and managed to support vessel cleanliness and regulatory compliance, with consideration given to safety requirements and environmental impact. These practices are intended to reduce operational risks and support efficient onboard operations.

Cleaning activities form an integral part of vessel operations, covering both essential maintenance tasks in the engine room and routine cleaning of crew and galley areas. Beyond hygiene considerations, structured cleaning practices may support overall operational efficiency. This is influenced by cleaning procedures as well as the suitability and performance of the cleaning products applied.

The ultrasonic cleaning equipment has been assessed as effective and supportive of operational efficiency, based on operational use and feedback.

-------------- Univan Ship Management Ltd, Deputy Fleet Manager

Our solutions cover a wide range of essential cleaning and maintenance tasks on board. Designed for the demands of maritime operations, these cleaning products are purpose-developed for shipboard use rather than adapted from general industrial applications. They address the specific challenges of marine environments, including exposure to seawater, fuel residues, salt buildup, and heavy machinery.

Chemicals and equipment are selected with crew usability, safety considerations, and regulatory compliance in mind. Cleaning solutions are supported by dedicated customer service, technical support, and advisory assistance, ensuring reliable access to products and guidance when required.

Packaging: Transition to Unbleached Cartons

Sustainability considerations extend beyond the performance of cleaning solutions to include packaging and supply chain practices. As part of ongoing optimization efforts, carton packaging has been transitioned to unbleached paperboard, supporting a more responsible and environmentally conscious approach within maritime operations.

Why unbleached cartons matter

Bleached cartons are manufactured using chemical processes that strip away the natural colour of paper pulp, producing a bright white finish. While this may look clean, the bleaching process often involves chlorine and other chemicals, which consume significant water and energy, and can contribute to pollution and greenhouse gas emissions.

In contrast, unbleached cartons retain the natural brown colour of the pulp and skip the harsh chemical treatments, making them a more eco-friendly and resource-efficient choice.

Key differences:

| Feature | Bleached carton | Unbleached carton (Unitor™) |

| Aesthetic | Bright white finish | Brown, visible fiber finish |

| Chemical use | Requires chlorine or other chemical agents to strip natural color | Eliminates the need for chemical bleaching |

| Resource intensity | Higher consumption of water and energy required | Lower consumption of water and energy during processing |

| Environmental output | Associated with discharge of chlorinated compounds and higher manufacturing emissions | Reduces industrial pollution and greenhouse gas emissions footprint |

This packaging change is one step in our ongoing effort to enhance the sustainability profile of our entire product offering.

For all enquiries

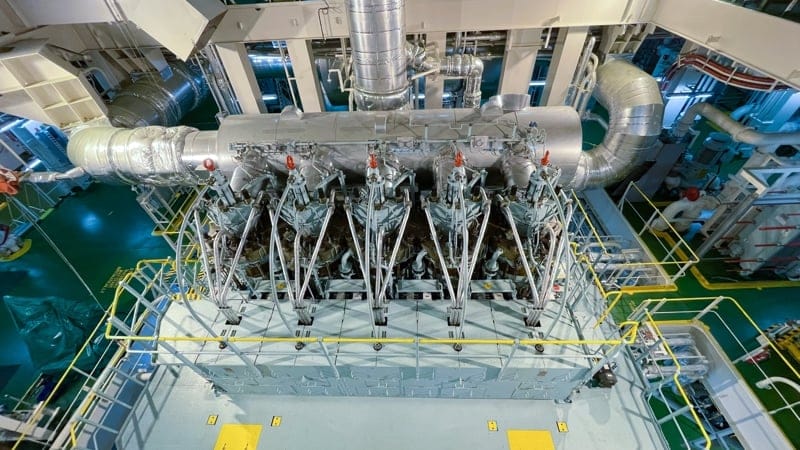

Engine room cleaning

Fartak B.O insights

Exploring Marine Product Standards

As transparency across product lifecycles becomes increasingly important, ecolabels support informed and responsible product choices.

Probiotic Treatment for Blackwater Systems

One common cause of sewage treatment system malfunction is the use of unsuitable chemicals. Probiotic treatment solutions can support system balance and performance by promoting biological processes within

The hidden costs of ineffective chemical cleaning in shipping

Ineffective chemical cleaning practices can lead to increased maintenance requirements, safety risks, and potential non-compliance with environmental regulations. This insight explores common challenges in chemical management and outlines practical considerations to support operational efficiency and regulatory

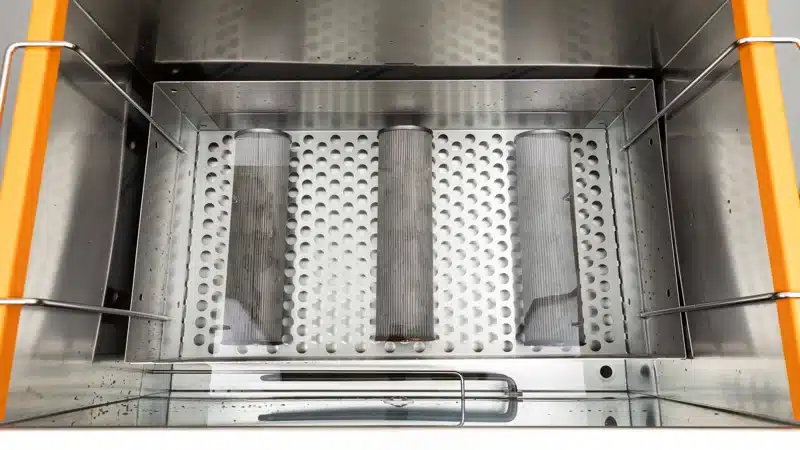

Don't Forget the Filters!

During the implementation of IMO 2020 fuel requirements, fuel filters can sometimes be overlooked. Blocked filters may lead to increased manual cleaning for crew and potential damage to filter components, affecting operational efficiency.

Featured Offers

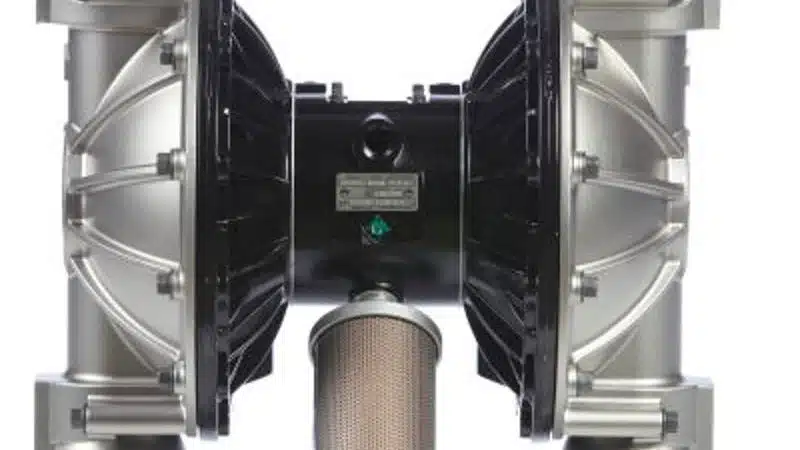

Maritime-Grade Durability: Discover the Unitor™ Aeroflow AODD Pump

Fluid transfer on board vessels involves a range of demanding tasks, from handling bilge residues to supporting cargo hold cleaning operations. Pump systems used in these applications must be robust, reliable, and suitable for use in marine environments.

In areas where space is limited, vapours may be present, and access to power sources is restricted, conventional pumping solutions can present operational challenges. Air-operated double diaphragm (AODD) pumps are designed to support safe and flexible fluid transfer in such conditions, offering durability and suitability for marine applications.

Why ultrasonic cleaning matters for your vessel

In the demanding marine environment, efficient maintenance is vital to keep vessels operational and compliant. Ultrasonic cleaners offer a cutting-edge solution for cleaning intricate ship components, ensuring optimal performance and extending equipment lifespan.

Effective Cleaning Solutions for Engine Rooms and Decks

Maintaining a clean engine room and deck isn’t just about appearance, it’s about performance, safety, and cost savings.

Raising standards of safety and efficiency through high pressure cleaning

High-pressure cleaning technology is redefining onboard maintenance by offering powerful performance, reduced chemical dependence, and measurable gains in safety, sustainability, and productivity.

Our Solutions

Maintenance Cleaning Chemicals

Maintenance cleaning chemicals are available across a broad product range to support a variety of onboard cleaning tasks, including decks, superstructure, stores, engine components, tanks, and bilges. Products are manufactured in accordance with recognised quality and environmental management standards, supporting consistent performance and responsible environmental practices.

Fluid Handling and Transfer Equipment

Fluid handling and transfer equipment covers a broad range of solutions, including air-driven double diaphragm pumps, lever and barrel pumps, chemical applicators, and grease pumps. Equipment is designed to be compatible with a wide range of chemicals and fluids, supporting demanding onboard handling and transfer tasks.

Biological Cleaning and Treatment Solutions

Biological cleaning and treatment solutions include a range of detergents and treatment products designed to support safe and efficient organic waste management. These products contain naturally selected microorganisms that break down organic compounds into water and carbon dioxide.

They are formulated for use in applications such as drain lines and grease traps, surface cleaning and odour control, as well as septic and waste treatment on board vessels.

Galley & Accommodation Cleaning

Galley and accommodation cleaning solutions support effective hygiene management and contribute to a safe and healthy onboard environment. A range of products is available, including detergents, defoamers, flocculants, bio-based cleaning products, as well as mixing and dosing equipment designed to support these essential cleaning tasks.

For crew personal care, suitable products such as hand cleaners, sanitizers, and skin protection solutions are also available.

Need advice?

With experienced teams operating across multiple port locations, practical local knowledge and industry expertise are applied to identify appropriate and effective solutions tailored to operational requirements.